Are you lazy? I am. I always try to find the easiest way. When someone calls me lazy, I take it as a compliment. You should too, provided that you are going about it the right way.

I spend a lot of time on the plant floor and see way too many people working harder than they need to. I am not saying that the work doesn’t have to be done, that we can skimp on safety, quality, productivity or almost anything else.

What we can skimp on, and should not be doing at all is unnecessary tasks. One of the problems is that people in the plant are too close to it. They see something they have been doing for years and don’t question it. More precisely, they do not see something they have been doing for years.

It probably made sense at one time but does it still? There is a story about a British Army lookout post to raise the alarm if Napoleon’s fleet was sighted. The post was still manned more than a century later. I was in a plant that had installed an automated system to collect production data. A year after installation, they were still collecting the data by hand as well. I understand running systems in tandem until they prove themselves. The issue in this plant was that nobody had ever thought to discontinue the manual system.

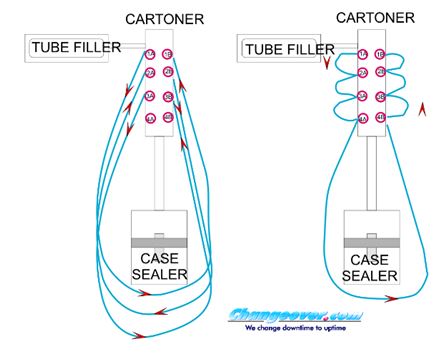

In another plant setup of a cartoner was supposed to require two people, working in tandem on each side of the machine. Getting two people in the same place at the same time turned out to be difficult so one person would do the setup. They would make an adjustment on one side of the machine, walk around the end of the line and make one on the other side. They spent 5 minutes walking back and forth in addition to the adjustments. (We timed it) One of the operators asked why they couldn’t make all the adjustments on one side then do the other side. There was no reason and this was implemented.

It had made sense at one time, it no longer did. So they stopped doing it.

You need to go out on your line and look at everything that is being done. Then you need to ask “Why?” Ask the operator why they are doing something and if the answer is because we have always done it like this, ask what happens if they stop. If the answer is “Nothing.”, stop doing it (Observing the process for implementing changes, of course)

Look at what is being done and if unnecessary, stop doing it. If it can be simplified, improved or made easier, do that.

Be lazy! Find an easier way.