Robot Machines

Used Robot Equipment

Everybody know what a robot is but ask 3 different people and you’ll get 4 different definitions. Wikipedia defines a robot as: A machine—especially one programmable by a computer—capable of carrying out a complex series of actions automatically.

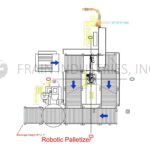

Robots are used in packaging for a variety of applications including palletizing, case packing, filling, line loading, labeling, sorting and stacking and more.

Some of the key parameters to be considered when selecting a robot for any operation:

Floor space – Most robots must be enclosed in a cage or protective guarding large enough to assure that it cannot ever reach outside the safety perimeter. Even if the robot’s normal range of motion is limited, the cage still needs to contain the maximum possible. NOTE: This does not normally apply to collaborative robots.

Speed – Robot speed is typically measured in inches per second. Generally, the heavier the load, the slower the robot will move.

Load capacity – The normal and maximum possible weight that the robot must handle must be considered.

Degrees of freedom required – Degrees of freedom is the number of directions that a robot can move at one time. Six degrees of freedom are required to reach any position in a volume from any angle. The human arm has 6 degrees of freedom. It is usually a function of the number of articulations in a robotic arm.

Five types of robots in common use in packaging:

Articulated arm – Articulated arm robots come in all sizes for lifting ounces to hundreds of pounds. They can have six or more degrees of freedom and are useful for performing complex tasks that may vary significantly from day to day.

SCARA (Selective Compliance Assembly Robot Arm) – SCARA robots typically have 3 degrees of freedom X-Y-Z. They can operate at high speeds on repetitive tasks such as placing candies into thermoforms.

Delta – Delta robots are usually vertical as shown. They have 3 degrees of freedom, X-Y-Z but can have additional degrees of freedom such as rotation added at the end of the arm. They are capable of operating at very high speeds. Picking cookies off of a belt and placing them on a flow wrapper infeed at 150ppm + is child’s play for a delta.

Gantry – Gantry robots, also called Cartesian robots, consist of 2 rails supporting a third rail. The 3rd rail runs on the X axis across the 2 support rails. A head mounted on the 3rd rail runs in the Y axis. The head is mounted to the Y rail with a mechanism that allows it to move up and down in the Z axis. A “wrist” mounted at the bottom of the Z arm can provide additional degrees of freedom.

Collaborative – Collaborative robots are robots designed to operate without the safety guarding normally required by other robots. SAFETY NOTE: This is application dependent and safety guarding may sometimes be required.

Robots are just another machine that is available to automate industrial and other processes. Their biggest advantages are their versatility and standardization. Robots are mass produced in large numbers which means that their cost is low compared to purpose built machines performing similar functions.

Related Categories

Robot Equipment In Stock

Fanuc Robot Robotics M-410IC / 185

- Manufacturer: Fanuc

- Model Number: M-410IC / 185

- Frain Number: 5J4340

Fanuc, 4 axes, servo driven, robotic case palletizing, automatic pallet stretch wrapper system, with number of cases per minute – depending on materials and application. Capable of moving product from floor level up to 123" in height, and has range of motion of 720 degrees, rated to maximum pick-up weight of 185 Kg. Equipped with vacuum pic-n-place head mounted on robotic arm with 123.72". maximum horizontal reach and has vacuum pump. Remote control panel has Fanuc R30iB controls with digital hour counter and auto / manual switch, fault, fault reset, power and e-stop push button controls, also has hand held, touch pad controller with display.

Get a Free Quote Call: 630-629-9900Fanuc Robot Robotics M-410IC / 110

- Manufacturer: Fanuc

- Model Number: M-410IC / 110

- Frain Number: 5J2920

Fanuc, Model M-410IC/110, bag palletizer, 4 axes, articulated rotary joint, servo driven, robotic, pic-n-place arm capable of palletizing and depalletizing and rated from 5 to 15 cycles per minute with number of product – depending on materials, application, machine configuration and pack pattern. Unit is capable of moving product from floor level up to 88" in height, and has range of motion of 720 degrees, rated up to maximum pick-up weight of 110 Kg. Equipped with forked vacuum bag head mounted on robotic arm with 94.6" maximum horizontal reach and has vacuum pump. Remote control panel has Fanuc R30iB controls with digital hour counter and auto / manual switch, fault, fault reset, power and e-stop push button controls, also has hand held, touch pad controller with display. Mounted on platform style base.

OAD: 94"L x 60"W x 101"H (Robot)

Get a Free Quote Call: 630-629-9900Fanuc Robot Robotics M-410IC / 185

- Manufacturer: Fanuc

- Model Number: M-410IC / 185

- Frain Number: 5J2780

Fanuc 4 axes, servo driven, robotic case palletizing, automatic pallet stretch wrapper. Unit is capable of moving product from floor level up to 123" in height, and has range of motion of 720 degrees, rated up to maximum pick-up weight of 185 Kg. Equipped with vacuum pic-n-place head mounted on robotic arm with 123.72". maximum horizontal reach and has vacuum pump. Remote control panel has Fanuc R30iB controls with digital hour counter and auto / manual switch, fault, fault reset, power and e-stop push button controls, also has hand held, touch pad controller with display.

OAD: 97"L x 54"W x 135" (Robot only)

Get a Free Quote Call: 630-629-9900Ixapack Global Robot Robotics REMOVAL STRAW>

- Manufacturer: Ixapack Global

- Model Number: REMOVAL STRAW>

- Frain Number: 5H9464

Ixapack Global servo driven straw applicator. Equipped with 32" diameter dual roll stand, servo driven cutting cylinder, (2) 38" long vacuum board accumulators, (8) head glue applicator, (8) head robotic pic and place and touch screen HMI.

OAD: 115"L x 80"W x 105"H

Get a Free Quote Call: 630-629-9900BMI / Benda MFG Robot Robotics UR3

- Manufacturer: BMI / Benda MFG

- Model Number: UR3

- Frain Number: R34570

Model UR3e

3Kg 6.6 lbs Payload

50mm 19.7 inches Reach

Programming – Polyscope graphical user interface on 12 inch touchscreen with mounting

IP Rating – IP54

Pose Repeatability +/- 0.03 mm, with payload, per ISO 9283

Footprint – Ø 128 mm

Materials – Aluminum, Plastic, Steel

Control Box

IP classification – IP44

I/O power supply – 24V 2A

Power source – 100-240VAC, 47-440Hz

Physical

Control box size -18.7 in x 16.7 in x 10.6 in

Item #T1, Epick Two Cup End-Effector

Energy Source – Electricity

Gripper Mass – 710g

Vacuum Level – 80%

Vacuum Flow – 12L/min

Item #T2, Air Pick Two Cup End-Effector

Energy Source – Compressed Air

Gripper Mass – 332g

Vacuum Level – 85%

Air Consumption – 135.9L/min

ABB Automation Robot Robotics IRB460-M2004

- Manufacturer: ABB Automation

- Model Number: IRB460-M2004

- Frain Number: 5H5860

ABB Model IRC5M2004, (4) axis, end of the line, robotic, pick n place palletizer arm rated up to 2,190 cycles per hour on a 60 Kg load with number of product – depending on materials and application. Operating range: R-axis (rotation) 320°, Reach 2.4m (7.8 Ft), Maximum handling capacity of 110 Kg, (243 lbs). Ambient temperature range during operation of 0 Deg C (32 Deg F) to 45 Deg C to (113 Deg F). with relative humidity of 95% maximum. Remote Model IRC5 single cabinet controller with touch pad and hand held controls has operator interface with motors on, cycle start, request to enter, S T empty pallet and e-stop push button controls. Mounted on 42" x 42" ground fastened, pedestal style base with enclosed cage style safety guarding.

OAD: 105" L x 50" W x 96" H Robotic Arm

28" L x 29" W x 44" H Control Cabinet