Gravity Pressure Machines

Used Gravity Pressure Equipment

Gravity liquid fillers or pressure liquid fillers are designed to fill containers using pressure of the liquid. Pressure on the liquid is created by either gravity or through the displacement of a pump. Gravity liquid filler or pressure liquid filler machines and equipment are designed to fill liquid into a container through nozzles. The nozzles on a pressure / gravity filler is designed to insert into the neck of the container while a collar makes contact with the neck of the container. The force of the neck pushing up on the collar causes the nozzle to open and to fill the container with product. The product is held under pressure either in a product holding tank above the filling nozzles or by pumping the product into the individual nozzles above the filling point. The nozzles on a gravity / pressure filler are designed to fill the container to a certain level above the fill nozzle, to a point where the pressure necessary to fill above that point just exceeds the pressure of the liquid entering the nozzle. Any excess product at this point is re-circulated through the nozzle and into a product hold tank for subsequent filling. Once the container has been filled, the gravity / pressure filler raises the nozzles out of the neck of the container. When the collar stops making contact with the neck of the container, the nozzle will close and prevent any further product from dispensing.

Gravity / pressure liquid fillers can be used to fill different size containers because of their simply design. The same pistons on a gravity / pressure liquid filler can be used to fill different size containers or to fill different volumes within the container so long as the filling nozzle fits within the neck of the container. Gravity / pressure liquid fillers can be adjusted to fill to different levels by changing the spacers on the collar on the filling nozzles. The wider the spacers on the filling nozzles, the higher the nozzle will be inside the neck of the container, and the higher the product level of the final fill. The narrower the spacers on the filling nozzles, the lower the nozzle will be inside the neck of the container, and the lower the product level will be inside the container.

Gravity / pressure liquid fillers can be designed to be inline or rotary.

Related Categories

Gravity Pressure Equipment In Stock

Horix Filler Liquid Grav/Press HBP9-18

- Manufacturer: Horix

- Model Number: HBP9-18

- Frain Number: 5H2124

Horix Model HBP 9-18-59, Automatic, 18 head, rotary, pressure gravity filler with number of containers per minute – depending on materials and application. Maximum container diameter: 6-1/2" on round and rectangle containers when operating with 9 fill valves and height per application and machine configuration. All stainless steel contact parts. Equipped with 140" long x 4-1/2" wide plastic Delran product conveyor with worm screw to star wheel in feed and discharge and container guide rails, 30" OD turret, has (18) 5/8" OD nozzles set on 5" centers with 7-1/2" long x 6-1/2" wide rising container pedestals for bottom up fill, no container / no fill with overhead product feed system. Control panel has filler and conveyor start, stop switches and start, stop, e-stop push buttons. Mounted on heavy duty base frame.

OAD: 140" L x 56" W x 95" H

Get a Free Quote Call: 630-629-9900Simplex Filler Liquid Grav/Press 400A

- Manufacturer: Simplex

- Model Number: 400A

- Frain Number: 5F2620

In line, 6-head, pressure overflow filler. Equipped with 4-1/2" wide conveyor with adjustable side rails, six 3/8" OD nozzles mounted on 65" long height adjustable slide bar & product tank with float valve level control. Can handle water-thin foaming or non-foaming to medium viscosity fluids. All stainless steel contact parts. Speeds dependant on materials and application.

OAD: 120" L x 36" W x 64" H

Get a Free Quote Call: 630-629-9900Accutek Filler Liquid Grav/Press APOF10

- Manufacturer: Accutek

- Model Number: APOF10

- Frain Number: R28310

Accutek, Model APOF10, automatic, inline, 10-head, stainless steel, pressure gravity, overflow filler with number of containers per minute – depending on materials and application. Equipped with 120" long x 6" wide Delran container conveyor, pneumatic container indexing, (10) 5/8" OD stainless steel diving nozzles, 72" long drip tray, product overflow tank and 1½ HP centrifuge pump. Touch screen operator interface controller. Mounted on stainless steel frame with casters and leveling legs.

OAD: 125"L x 56"W x 78"H

Get a Free Quote Call: 630-629-9900MRM Elgin Filler Liquid Grav/Press 24HEAD

- Manufacturer: MRM Elgin

- Model Number: 24HEAD

- Frain Number: 5G7930

MRM Elgin, automatic, stainless steel, 24 head rotary pressure gravity filler. Rated from 40 to 240 containers per minute – depending on materials, application and machine configuration. Container size: up to 3.5" in Diameter: up to 9½" in Height with proper change parts. Equipped with a wormscrew to star wheel in feed and star wheel discharge, 38" diameter table with (24) ½" OD stainless steel nozzles set on 4" centers, centrifugal product pump, holding tank floating level sensor, no container / no fill and variable speed controller for pump and filler. Mounted on stainless steel base frame with drip pan.

OAD: 60"L x 60"W x 82"H

Get a Free Quote Call: 630-629-9900MRM Elgin Filler Liquid Grav/Press 24 HEAD

- Manufacturer: MRM Elgin

- Model Number: 24 HEAD

- Frain Number: 5H3612

MRM Elgin, automatic, 24 head, stainless steel, rotary, fill to level filler, rated from 48 to 240 containers per minute – depending on materials, application and machine configuration. Container size: up to 3.5" in Diameter: up to 9-1/2" in Height (with proper change parts). Equipped with worm screw to star wheel in feed and discharge, top gear drive and 40" OD table with (24) 3/8" OD stainless steel nozzles set on 4" centers, bottom up fill, no container / no fill with vari-speed contoller and centrifugal product feed pump. Control panel has machine, filler, belt, start, stop and e-stop controls. Mounted on (4) leg stainless steel base frame with safety guarding.

OAD: 70" L x 68" W x 81" H

Get a Free Quote Call: 630-629-9900Liquid Packaging Solutions Filler Liquid Grav/Press 306-150MOD1

- Manufacturer: Liquid Packaging Solutions

- Model Number: 306-150MOD1

- Frain Number: 5H2120

Equipment Express Model, 306-150M0D, 14 head, stainless steel, automatic, inline left to right overflow filler with number of containers per minute – depending on materials and application. Equipped with 144" long x 4" wide flexlink table top vari-speed container conveyor with adjustrable guide rails, pneumatic indexing and 16" OD disc transfer disc. 84" long slide bar, 14 diving (5/8" OD) nozzles with 30" long x 24" wide x 20" high plastic product hopper and feed pump. PLC with touch screen controller and read out, filler and conveyor speed control dials, filler and pump close, open, out and bypass switches with e-stop. Mounted on casters with leveling legs.

OAD: 144" L x 57" W x 72" H

Get a Free Quote Call: 630-629-9900Liquid Packaging Solutions Filler Liquid Grav/Press LPS2000

- Manufacturer: Liquid Packaging Solutions

- Model Number: LPS2000

- Frain Number: 5H0692

Liquid Packaging Solutions, 15 head stainless steel, automatic, in line overflow filler with size and number of containers per minute – depending on materials and application. Equipped with 128" long x 4-1/4" wide table top container conveyor with adjustrable guide rails and pneumatic indexing. 48" long slide bar currently has 15 diving filling heads with 1/2" OD nozzles, 24" long x 18" wide x 20" high poly product feed and overflow tank with centrifugal pump. Control panel has A/B PLC with touch screen operator controls and read out, vari-speed control dials. power up, height down and e-stop controls. Mounted on stainless steel base frame with casters and height adjustable leveling legs.

OAD: 128" L x 48" W x 69" H

Get a Free Quote Call: 630-629-9900Solbern Filler Liquid Grav/Press LFF 103

- Manufacturer: Solbern

- Model Number: LFF 103

- Frain Number: 5G2609

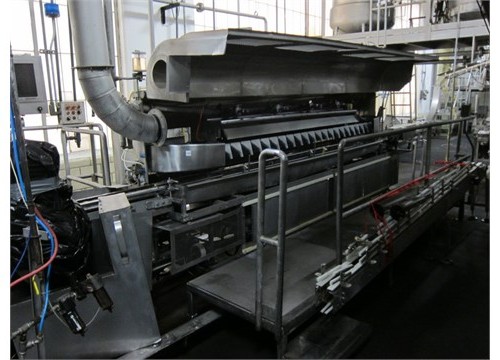

Solbern Model LFF 103, constant flow filler. Number of containers per minute – depending on material and application. Equipped with 52 spouts and a lugged chain container conveyor set on 6" centers. Traveling funnels in a endless chain move beneath continuous flow of liquid. The traveling funnels are synchronized to the traveling containers beneath and direct the flow of product into the containers. Containers are slightly over-filled at a predetermined angle. The slight overflow is captured and returned to processing for maximum yield. Adjusting the container filling angle regulates the total fill volume and headspace. The can flange acts as a pouring spout. No product touches the sides of the container.

OAD: 179"L x 58"W x 85"H

Get a Free Quote Call: 630-629-9900Biner Ellison Filler Liquid Grav/Press F52

- Manufacturer: Biner Ellison

- Model Number: F52

- Frain Number: 5G3636

Biner Ellison Model F52, automatic, 18 station, top driven, rotary, pressure gravity filler rated from 18 to 180 containers per minute – depending on materials and application. Maximum container size: 6-1/2" OD round and 5-1/4" x 5-1/4" square, with fill range from 0 to 128oz per station, capable of handling glass, plastic and metal containers as well as free flowing to semi viscous product with proper change parts. Equipped with 60" long x 4-1/4" wide container conveyor with star wheel in feed / discharge, 52" OD turret with 18 bottom up filling stations, set on 9" centers with 1" OD nozzles. Control panel has filler, drive, conveyor on / off switches with speed control dials and mounted on (4) leg base frame with drip basin.

OAD: 80"L x 64" W x 78" H

Get a Free Quote Call: 630-629-9900MRM Elgin Filler Liquid Grav/Press IFL SERIES

- Manufacturer: MRM Elgin

- Model Number: IFL SERIES

- Frain Number: 5F9490

MRM Elgin, Model, IFL Series, 10 head stainless steel, gravity overflow filler. Container size up to 7" in Diameter. Equipped with 120" long x 3-1/4" wide Delran conveyor, adjustable guide rails, 10 filling heads with 5/8" OD nozzles on 56" slide bar and overflow tank with float valve and centrifugal pump. Control panel with filler, conveyor and pump on / off switches. Speed dependant on materials, application and machine configuration.

OAD: 134" L x 44" W x 78" H

Get a Free Quote Call: 630-629-9900New Jersey Filler Liquid Grav/Press 12HEAD

- Manufacturer: New Jersey

- Model Number: 12HEAD

- Frain Number: 5F7701

Njm Model 12-Head rotary, gravity / overflow filler rated from 40 to 90 containers per minute – depending on materials and appliction. Container size: 1" to 5-1/16" in Diameter; 2" to 14" in Height capable of handling plastic and glass containers round and other shapes which can be controlled by worm screw. Equipped with 112" long x 2-1/2" wide conveyor, worm screw to star wheel in feed and discharge, no container / no fill, 28" OD turrett with overhead drive and (12) 5/8" OD nozzles set on 5-1/4" centers with stainless steel product hopper float valve, start / stop and e-stop push button controls.

OAD: 112" L x 72" W x 88" H

Get a Free Quote Call: 630-629-9900